Testing the Weather Performance of Louvres and Reviewing BS EN 13030

The purpose of an external louvre, often called a ‘weather louvre’, is to enable airflow whilst rejecting rain and other elements.

The purpose of an external louvre, often called a ‘weather louvre’, is to enable airflow whilst rejecting rain and other elements.

The Industry standard for weather testing of louvres in the UK was developed by BSRIA in collaboration with HEVAC (Heating, Ventilation and Air Conditioning Manufacturers Association), and was adopted in 2001 as British and European Standard: BS EN 13030:2001.

BS EN 13030:2001 tests louvres in 3 key performance areas:

-Water Penetration (Effectiveness): the ability to prevent rain penetrating the louvre;

-Pressure Drop (Discharge Loss Coefficient): how freely the louvre allows air to pass through;

-Overall Performance: a combined measure of the above

The HEVAC/BSRIA test method enables clients to relate one manufacturers’ performance against another at set benchmarks, helping to make specification easier. The tests themselves are based on methods that simulate the real-life operating conditions a louvre will undergo when installed. The rain rejection performance can be established over a wide range of conditions using simulated wind speed, water and ventilation rates.

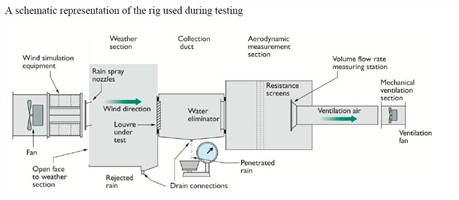

Figure 1 shows a schematic representation of the rig used by BSRIA during a typical test.

Figure 1 – Typical BSRIA rig for testing of weather louvres.

This diagram is taken from a BSRIA weather test report, examples of which can be found here. A description of how the rig is used for each type of test is given in the following sections.

Test 1: Water Penetration (Effectiveness)

Each test is preceded by a suitable ‘pre-test’ soak. Following this, the test itself is run until the results become stable but for a minimum of 30 minutes.

As represented in Figure 1, this test is achieved by fan driven, wind simulation equipment driving air towards the louvre at a standard face velocity of 13m/s (30mph), whilst nozzles spray water parallel to the airstream at a rate of 75l/h (litres per hour), to simulate rain. In the weather section (labelled above) the rejected rain is collected and drained. Behind the louvre (to the right on the diagram) is a collection duct, which is sealed at the other end by a water eliminator. In this area the penetrated rain is collected and measured. In addition to the simulated wind at 13m/s, air is drawn through the louvre by a mechanical ventilation unit at a range of set face velocities (0, 0.5, 1.0, 1.5, 2.0, 2.5, 3.0 and 3.5 m/s).

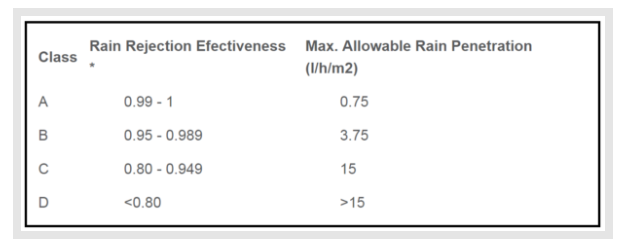

Table 1 below summarises the volume of allowable rain penetration for the different classes of weather performance. It is worth noting that a louvre can have a different weather performance class at different face velocities. For example, a louvre could have Class A weather performance at a face velocity of 0.5m/s, but only Class C weather performance at a face velocity of 2.0m/s.

Table 1 – benchmark performance for the Water Penetration Test

* A rain rejection effectiveness of 0.99 indicates that 99% of the incident rain does not penetrate the louvre.

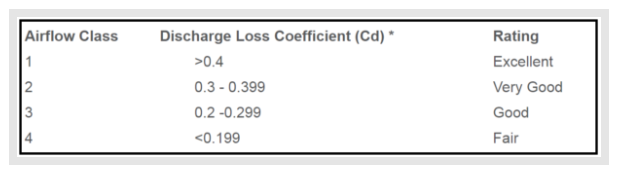

Test 2: Pressure Drop (Discharge Coefficient – Cd)

The purpose of this test is to calculate the Discharge Loss Coefficient (Cd), a measure of the louvre’s resistance to air flowing through it. This test is done at a number of different air velocities. The higher the value of Cd, the less resistance the louvre offers to air flowing through it.

For this test the aerodynamic measuring section (AMS), as represented in Figure 1, is separated from the main rig, and the louvre is mounted in the upstream opening. Pressure tappings in the plenum walls of the AMS allow measurement of the static pressure within the plenum during testing. The volume flow rate is calculated from the differential pressure at the measuring cones. An accurate reading of this can be measured due to the fact that the plenum has a set of settling screens within to produce even flow through the cones.

Table 2 – benchmark performance for the Pressure Drop test

*Cd represents the fraction of the physical area of flow which is the effective area of flow

Overall Performance

The Overall performance rating is obtained simply by multiplying the Rain Rejection Effectiveness and the Discharge Loss Coefficient:

Overall Performance = Rain Rejection Effectiveness x Cd

This gives a single, simple measure of the overall louvre performance. However, due to the simplistic nature of this overall measure, louvres with very different characteristics can have similar overall performance ratings. For example, a louvre with a very good discharge loss coefficient will often have a much lower rain rejection effectiveness and vice versa. Therefore good airflow characteristics can sometimes mask poor weather performance.

Factors that may affect real louvre performance, compared to the test

-Site Conditions

-Installation – may not be flush with a wall

-Louvre size – standard test size is 1m2

-Orientation of the louvre blades

-Bird/rodent/insect guards

-Structural elements

Problems with this Classification System

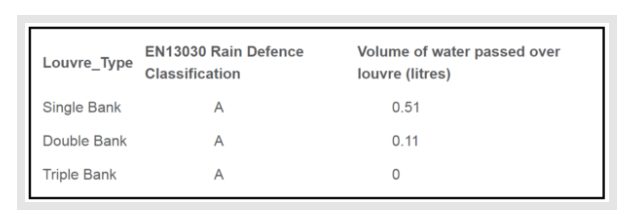

A number of problems associated with the water penetration classification were identified in a 2013 blog post by Graeme Clarke of Colt UK (reference below). The article emphasises the problem with classifying louvres which have 99% effectiveness in the same group as those with 99.9%. For example, the table below shows that three Class A weather louvres can have very different numerical results in a rain penetration test:

Table 3 – Comparing volume of water passed over single, double and triple bank louvres.

The volume of water passed over the single bank louvre (i.e. the water allowed to pass into the building) is substantially greater than the volume of water passed over the double bank louvre, whilst the Class A triple bank louvre had no measureable water penetration at all. Furthermore, these tests were all carried out on standard 1m2 panels. For larger panels the difference in the volume of water penetration would need to be scaled up by the same factor.

The results also highlight that the design of the single bank extruded louvre blade tends to project incoming water deep into the building, whilst the double bank louvre tends to eject the water downwards, so preventing deep water penetration. As a result, the use of double or triple bank louvres, rather than the cheaper single bank, is generally recommended.

The above discussion leads us to conclude that, whilst EN 13030 is a useful guide for confirming the suitability of a louvre system for rain defence, it should not be relied upon for every project.

Reference Websites:

http://c-sgroup.co.uk/blog/intro-to-louvre-performance-testing/

http://www.buildingdesign.co.uk/arch-technical/gilberts-t/weather-louvres-high-performance-louvres.htm

https://www.bsria.co.uk/services/test/product-testing/weather-louvres-sand-rain/

http://blog.coltinfo.co.uk/blog/bid/141130/Not-all-Class-A-weather-louvres-are-equal

http://c-sgroup.co.uk/uk-en/wp-content/uploads/sites/29/2015/08/cs_louvre_specification_guide-1.pdf

https://www.bsria.co.uk/services/test/directory/

This article was written by Maxim Bird, Engineering Intern at Breathing Buildings.