Natural Ventilation Overview

Natural Ventilation - All Year Around

Natural Ventilation – all year around

When Breathing Buildings was founded in 2006, the UK had a problem. Schools built to be naturally ventilated were suffering from a huge gap between designed and real performance. The biggest issues were: heating bills multiple times what had been predicted, and indoor air quality characterised by unacceptably high levels of CO2.

These schools had been designed, as had buildings for many years, with their sole means of ventilation being natural ventilation, via manually openable windows. In summertime it got warm, but not excessively warm, and the natural ventilation design worked more or less as expected. But the UK is not renowned for its warm sunny climate. Our coastal, north-Atlantic climate is characterised by mild, damp conditions and rapid changes of weather.

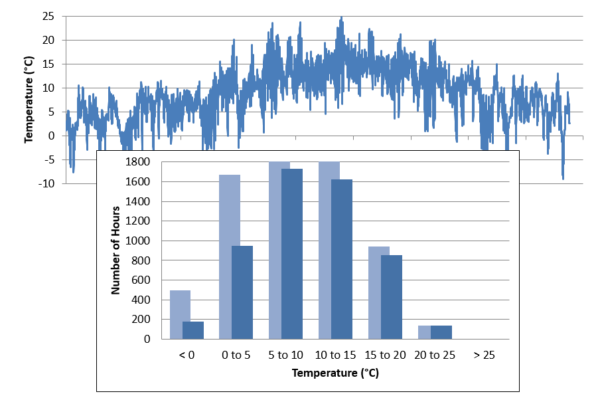

Take the Glasgow weather file as an example. The below figure shows the distribution of dry bulb external air temperature over the course of a year – data taken from the CIBSE TRY weather file.

What this shows is that the vast majority of occupied hours (darker blue bars) are at the lower end of the temperature scale. This tells us that, whilst the natural ventilation scheme of openable windows might work well in warmer weather, most of the occupied hours are actually too cold for the schools to make use of that simplistic ventilation design.

Common sense tells us that if the external air temperature is around 15degC or colder, people will not be satisfied with that air being brought directly into the occupied space. With a traditionally designed natural ventilation scheme, where the only means of ventilation is through opening windows, there are two ways of dealing with this issue:

1. Add a radiator or heater battery underneath the windows, to pre-heat incoming fresh air;

2. Reduce the opening to reduce the amount of (cold) fresh air being brought in.

The results of these two solutions are:

1. Increased energy use due to radiators/heaters working overtime to pre-heat incoming air, which they were never designed to do.

2. Poor and unacceptable air quality, caused by insufficient ventilation rates.

Studies conducted during the late 1990s and early 2000s identified exactly these issues, but it took researchers at Cambridge University, and eventually the founding of Breathing Buildings, to propose a solution. Here’s how it works:

Summing the heat gains in a typical classrooms, one might account for people – 30 people at 100W each, equipment – a few PCs at 50W and a projector at 100W, some solar gain, and perhaps some heat sink due to the thermal mass of the building and furniture. Summing these up, without accounting for any heat input due to radiators, one can comfortably assume a net heat input of around 3-3.5kW.

Taking a simple energy balance equation, applying 3kW of heat to the volume of air needed to properly ventilate a classroom (5-10 litres/sec/person), we can show that 3kW is sufficient to raise the temperature of air by 10-15degC. That means, if we could actually employ the heat which naturally occurs within every single classroom to pre-heat the incoming fresh air, we could raise the temperature of that air by 10-15degC; with no heating! Zero heating energy consumed.

This heat balance tells us, therefore, that if we are targeting a room air temperature of ~20degC, we don’t actually need ANY heating energy at all, until the external air temperature gets to ~5DegC. At 5degC and below, the energy balance equation tells us that 3kW of incidental heat gains are no longer sufficient to raise the maintained air temperature to 20degC, and we must use extra heating (e.g. radiators) to top up the heat input to the space.

So far so good, it’s fairly simple mathematics/physics, and none of the above is new. So what did Breathing Buildings bring to the party that people didn’t already know?

The unique, novel concept for which the e-stack system gained European Patent protection, was not the idea of trying to usefully employ the incidental heat gains, but a workable solution for how to re-cycle those heat gains and re-employ them for the purpose of pre-heating the incoming fresh air. The answer was mixing ventilation, the product was the e-stack, and one classroom at a time, it has changed the world of natural ventilation.

To find out more information about our Natural Ventilation solutions, please click here. Or alternatively, contact our office on info@breathingbuildings.com

(function(i,s,o,g,r,a,m){i[‘GoogleAnalyticsObject’]=r;i[r]=i[r]||function(){

(i[r].q=i[r].q||[]).push(arguments)},i[r].l=1*new Date();a=s.createElement(o),

m=s.getElementsByTagName(o)[0];a.async=1;a.src=g;m.parentNode.insertBefore(a,m)

})(window,document,’script’,’https://www.google-analytics.com/analytics.js’,’ga’);

ga(‘create’, ‘UA-103220203-1’, ‘auto’);

ga(‘send’, ‘pageview’);